Please call us at +44 (0) 7454 002956

INSIGHTS

'Should Cost' & 'Bottom-Up'

'Should Cost' is a detailed calculation of all costs associated with manufacturing a product. It is independent, based on proven benchmarks and factual data—not supplier quotes.

'Bottom-Up' estimating is the process of building total cost from the lowest level, such as calculating the cost of electricity to run a machine and then summing all individual elements to determine the overall cost.

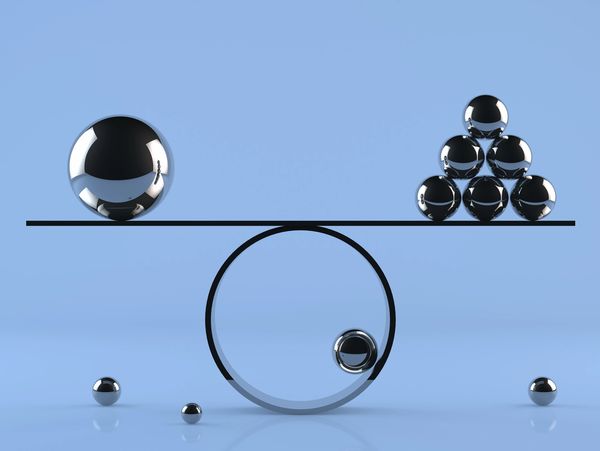

As shown in the chart, there is usually a substantial gap between the 'should cost' and the supplier quote.

This gap, along with the associated cost insights, provides a robust basis for supplier negotiations—often leading to significant cost savings.

Value Engineering (VA/VE)

Value engineering at the concept stage and value analysis at the mass production stage (VA/VE).

This systematic approach involves comparing the functions of your products with the associated costs we've calculated.

We collaborate with your design teams to identify lower-cost alternative designs.

We conduct scenario modelling to determine the best location for manufacturing or sourcing.

We make designs manufacturing-friendly, which naturally leads to lower costs.

Value for Money (VfM)

Value for Money (VfM) is often expressed as:

VfM = Total Lifetime Benefits – Total Lifetime Costs

This approach looks beyond the initial purchase price and considers the entire lifecycle of a product or service. It’s also known as:

- Lifecycle Costing

- Total Cost of Ownership (TCO)

Both concepts provide a holistic view of benefits and costs, helping organisations make informed decisions by factoring in long-term performance, maintenance, and sustainability rather than just upfront cost.

Fact-Based Negotiations

Negotiations driven by transparent cost data and objective analysis rather than assumptions. This approach uses detailed cost breakdowns, benchmarks, and should-cost models to build credibility, strengthen positions, and achieve fair, sustainable agreements.

Spend Analysis

Spend analysis involves collecting, cleansing, categorising, and analysing spend data to understand how money is spent.

It typically covers:

Supplier spend: suppliers you’re buying from and how much.

Category spend: What goods or services you’re purchasing.

Through spend analysis, companies can identify areas where there are opportunities for improved efficiency and cost savings through strategic sourcing.